When Hunter alums Gregory Kurgansky '18 and Benjamin Sanits '18 scheduled a vacation to Aruba, they didn't expect the coronavirus pandemic would cut the trip short and necessitate a 14-day quarantine together in Kurgansky's apartment. They quickly realized that the time sheltering in place could prove productive—and that even while they couldn't go out into the community, they could make things that would. Kurgansky and Sanits, both aspiring physicians, decided to combine their dual interests in medicine and technology to create much-needed personal protective equipment (PPE) for hospital workers. Using a 3-D printer and blueprints from the National Institutes of Health website, the Hunter grads began printing face shields, a piece of PPE that hospitals have reported are in short supply during the COVID-19 crisis.

Kurgansky first encountered 3-D printing during an internship in a lab at NYU Dental, and he gained further experience with the printers at New York Institute of Technology, where he is currently a first-year medical student—but neither he nor Sanits owned one of the expensive, specialized machines. They pooled their finances to order one on the Internet and spent the days waiting for its arrival reviewing designs. As soon as they began production, requests for their wares started coming in, from hospitals, paramedics, fire stations, and city agencies. When their two-week quarantine period passed, they kept working together while living apart, with each of them heading back home to their families.

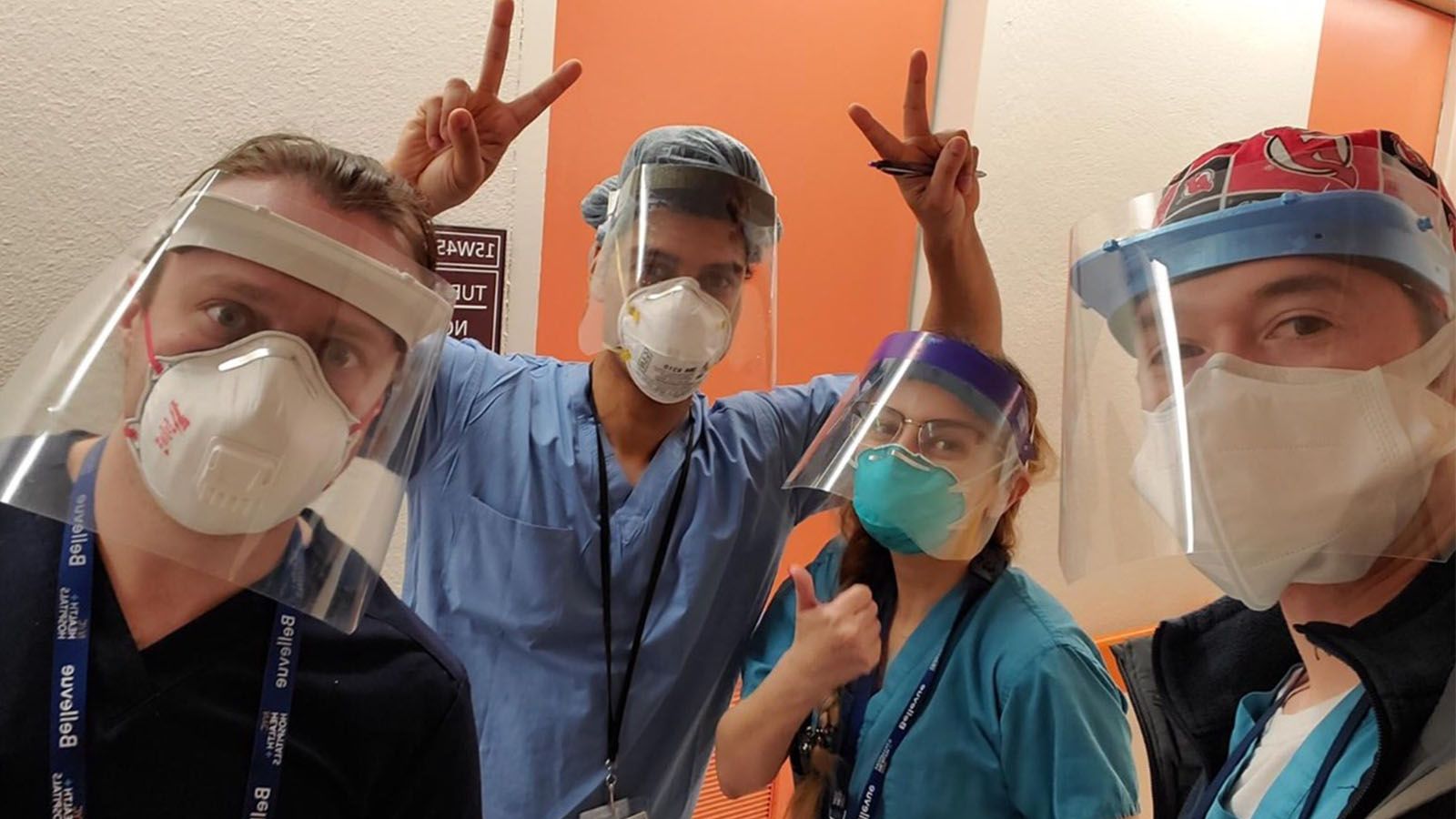

A successful GoFundMe campaign financed their supplies—and the purchase of a second 3-D printer—allowing them to expand production. As of mid-May, they have delivered more than 200 pieces of PPE to emergency workers. And in addition to printing durable multi-use face shields, they are also printing disposable ones for emergency situations, as well as vent-splitters, the devices that allow ventilators to serve multiple patients at once. The gear has served Brooklyn Hospital Center, NYU Langone Medical Center, Bellevue Hospital, and Jamaica Hospital Medical Center, among others.

Kurgansky and Sanits, both New York natives who met during their first year at Hunter, are pursuing careers in medicine, though pursuing different avenues. Kurgansky homed in early in his college career on health care issues, and his advisors steered him towards a Roosevelt House seminar on health policy. He wrote a thesis titled “Medical Deserts in an Urban Area,” and ever since, he has been alert to systemic shortages and issues in emergency preparedness. He pursued the pre-med track at Hunter, majoring in economics, and was recently accepted to a special program at the New York Institute of Technology that will enable him to take master’s degree courses in the summer. He hopes one day to treat patients in hospitals: “I like the acute setting, I like something where it’s changing and you’re not doing the same thing every day,” he says. He also wants to have a hand in hospital administration and health policy.

Sanits, who majored in chemistry with a concentration in bioinformatics and a minor in statistics, will matriculate at SUNY Downstate Medical Center in the fall. He is interested in continuing to pursue health care and technology simultaneously, maybe ultimately concentrating in an area of medical practice that’s tech-forward. Since graduating from Hunter, Sanits has been working as a medical scribe, a job that he is currently performing remotely. Also an avid and accomplished fencer—he was the captain of the Hunter team—he has worked as a fencing coach at schools through the New York City area. While schools are closed, his fencing career is on hold, but he says that the lessons of fencing serve him in all aspects of life. "It's a strategic game that requires quick thinking and decisiveness. You have to stretch your brain."

Right now, Sanits and Kurgansky are stretching their imaginations to come up with new ways their 3-D printing operation can serve the medical community. They are interested in hands-free devices—they designed a key chain device that opens doors—and they are exploring the possibility of using surgical paper to make masks. "This project was a manifestation of our desire to help, combined with our fascination with 3-D printable solutions," says Sanits. "The primary goal is to help those on the front lines because we know how stressful and scary it can be. If our project helps at least one person in this crisis, we made a difference."